Poor wiring practices, no testing, leads to trouble!

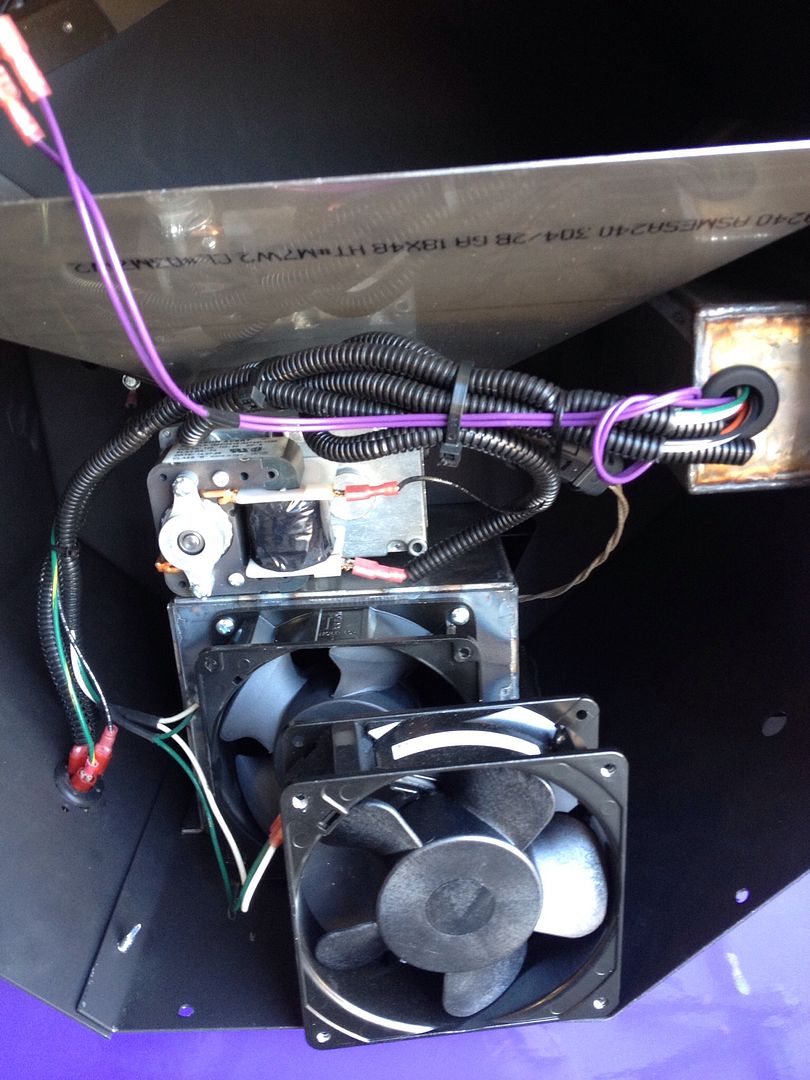

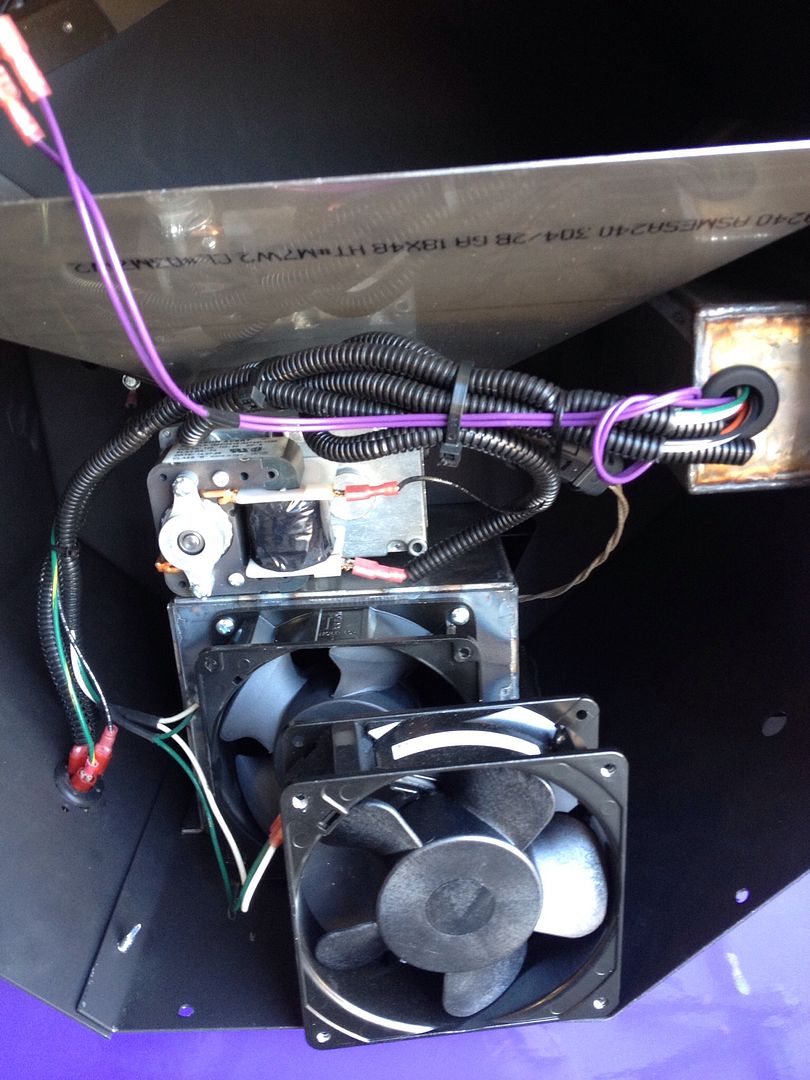

Unpacked my brand new 640 competition, got it all ready to go, plugged it in, hit start, element heats up, auger does not move. Unloaded the hopper and vacuumed it out, try it empty, does not move. Pulled the end cap off, metered the gear motor 120 volts, should be turning. Noticed the leads going to the coil were bent back due to tie wrapping the wires backwards as tight as a guitar string, this includes the thermocouple lead. Pulled the gear motor and checked the resistance, Zero. One of the posts on the motor was bent far enough to break the small copper coil wire. I soldered the wire back and bingo, motor works!

Noticed the wires going to the cord socket on the comp cart go through the original hole for the cord socket on the smoker. No bushing or anything to protect the wires from rubbing on the edge of the steel. I found a bushing that worked to clean up that potential future problem.

Inside the grill where the thermocouple wire comes in there is a 3/4" tall wade of silicon sealing the hole. This causes the end grill to not fit properly and the grill rests on the wire and silicon, why is the wire coming in where the grill sits? It won't be long befor the grill will rub a hole in the thermocouple wire.

Bottom line: A new customer, with food prepped and ready and people waiting, should not have to repair their grill on the first day of use due to poor wiring practices and no testing of the unit before it left the factory.

1. Clean up your wiring practices. Be sure there is no tension on the wire connections.

2. Put a bushing on the wires going to the socket on the comp cart.

3. Move the hole location for the thermocouple wire so that the grill will lay flat and not wear through the wire.

4. TEST EVERY UNIT BEFORE SHIPPING!!!

Sent from my iPhone

Noticed the wires going to the cord socket on the comp cart go through the original hole for the cord socket on the smoker. No bushing or anything to protect the wires from rubbing on the edge of the steel. I found a bushing that worked to clean up that potential future problem.

Inside the grill where the thermocouple wire comes in there is a 3/4" tall wade of silicon sealing the hole. This causes the end grill to not fit properly and the grill rests on the wire and silicon, why is the wire coming in where the grill sits? It won't be long befor the grill will rub a hole in the thermocouple wire.

Bottom line: A new customer, with food prepped and ready and people waiting, should not have to repair their grill on the first day of use due to poor wiring practices and no testing of the unit before it left the factory.

1. Clean up your wiring practices. Be sure there is no tension on the wire connections.

2. Put a bushing on the wires going to the socket on the comp cart.

3. Move the hole location for the thermocouple wire so that the grill will lay flat and not wear through the wire.

4. TEST EVERY UNIT BEFORE SHIPPING!!!

Sent from my iPhone